A 3D printer is a complicated machine that melts plastic into advanced 3D shapes. Upgrading one includes tinkering with sophisticated movement methods and elaborate electronics, with the added complexity of firmware modification.

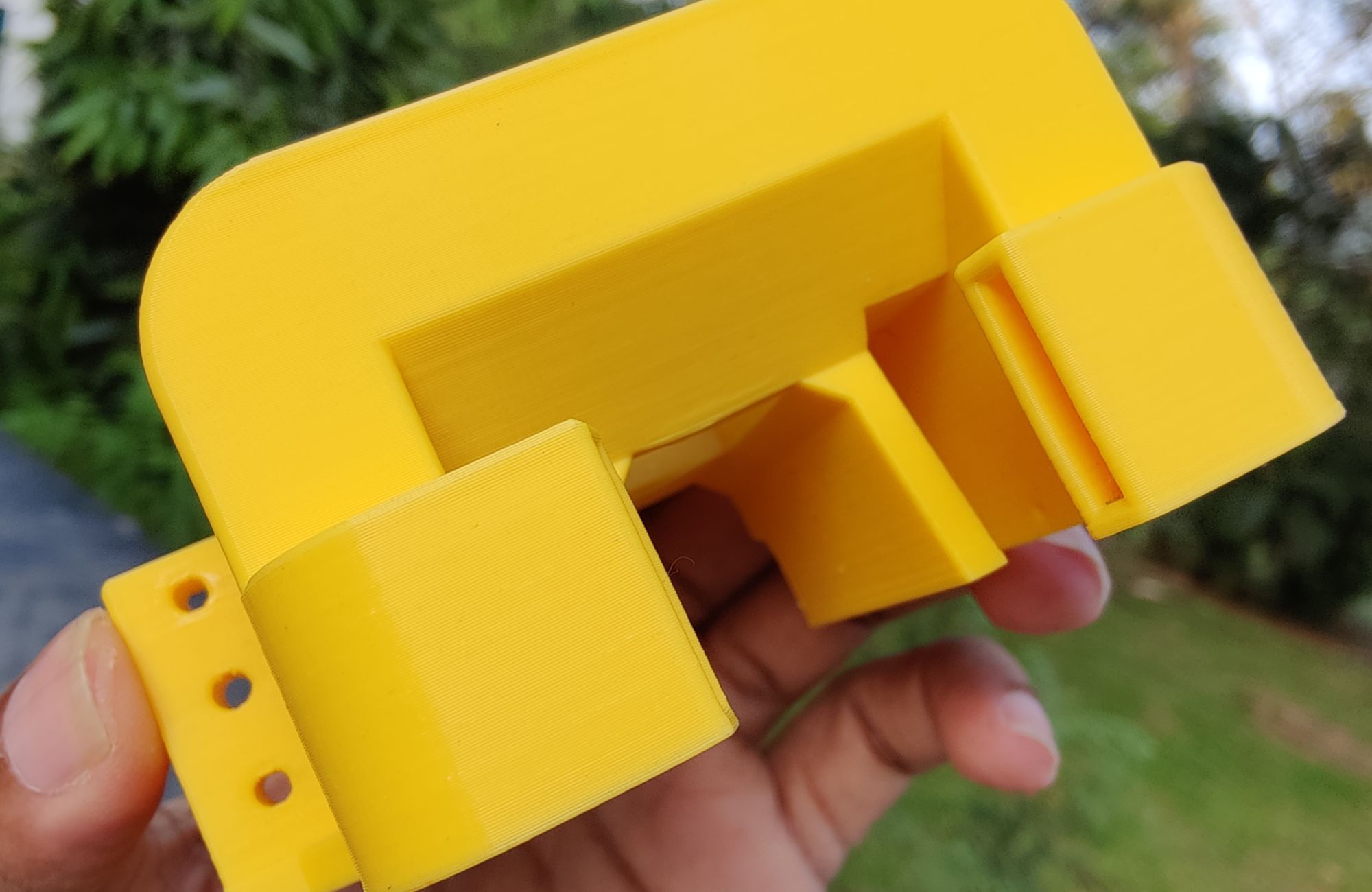

That also hasn’t deterred a rising variety of intrepid 3D printing lovers from buying entry-level 3D printers and modifying them to rival costly fashions. One of the common mods includes upgrading inventory Bowden extruders to direct drive extruders.

It might be honest to imagine that upgrading the print head itself would assure sufficient of an enchancment to justify the trouble concerned. However what if we instructed you that this costly improve typically decreases print high quality?

Confused? Learn on to search out out why an extruder improve isn’t as simple because it sounds.

Fantasy: Direct Drive Extruders Enhance Print High quality

Go to any 3D printing discussion board, and you’re sure to search out members complaining of poor print high quality proper after upgrading to direct drive extruders. You might attribute a few of these instances to defective improve elements and improper set up practices, however these aren’t remoted incidents.

In actual fact, 3D printing veterans is aware of that it’s nearly unattainable for even costly printers to match the out-of-the-box print high quality of the Creality Ender-3 printers. So, what’s taking place right here?

However first, let’s take a step again to know what direct drive extruders are, how they differ from inventory extruders, and why they’re thought of worthy upgrades.

What Are Bowden Extruders?

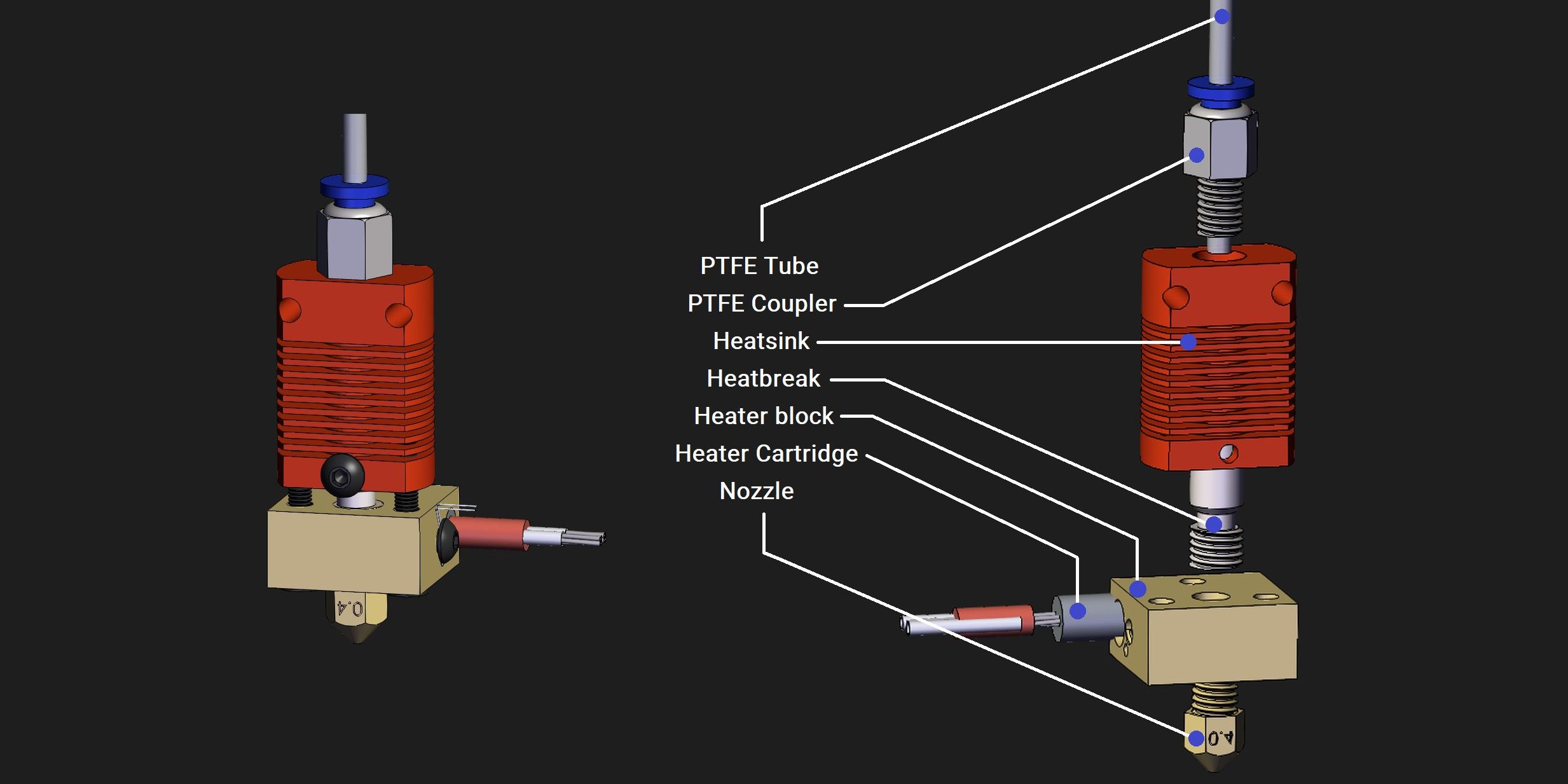

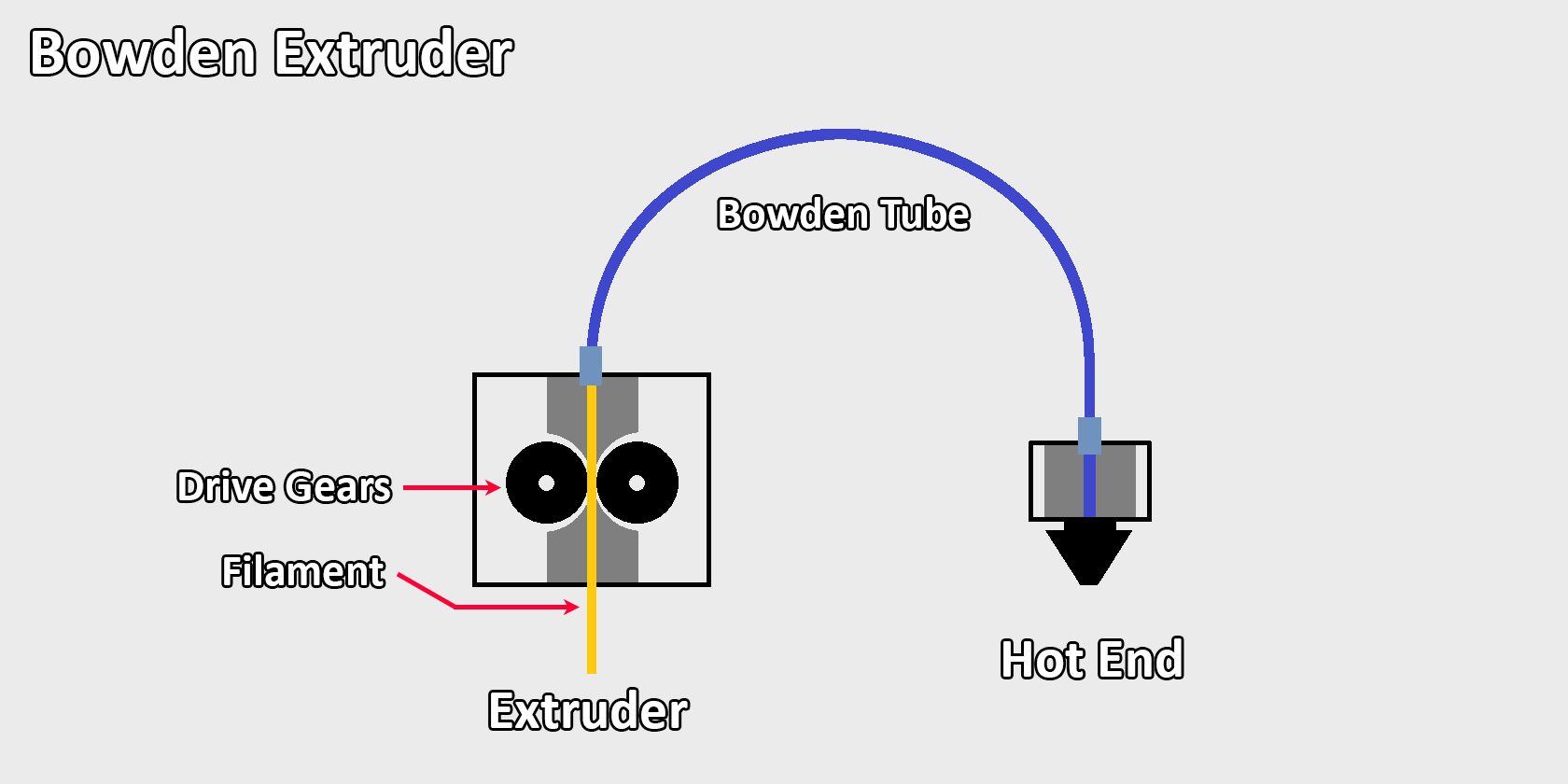

Standard entry-level 3D printers, such because the Ender-3, ship with Bowden extruders. This print head design bodily separates the extruder (which pushes filament into the nozzle) from the new finish meeting consisting of the warmth sink, warmth break, heater block, and nozzle.

These extruders get their identify from the considerably longer Bowden (or PTFE) tube connecting the extruder to the new finish meeting. This can be a comparatively easy design that’s cost-effective. However a Bowden extruder’s longer filament path additionally makes it practically unattainable to print versatile filaments.

You’re basically attempting to push a rope down a hose at that time. And that’s the place direct drive extruders come into the image.

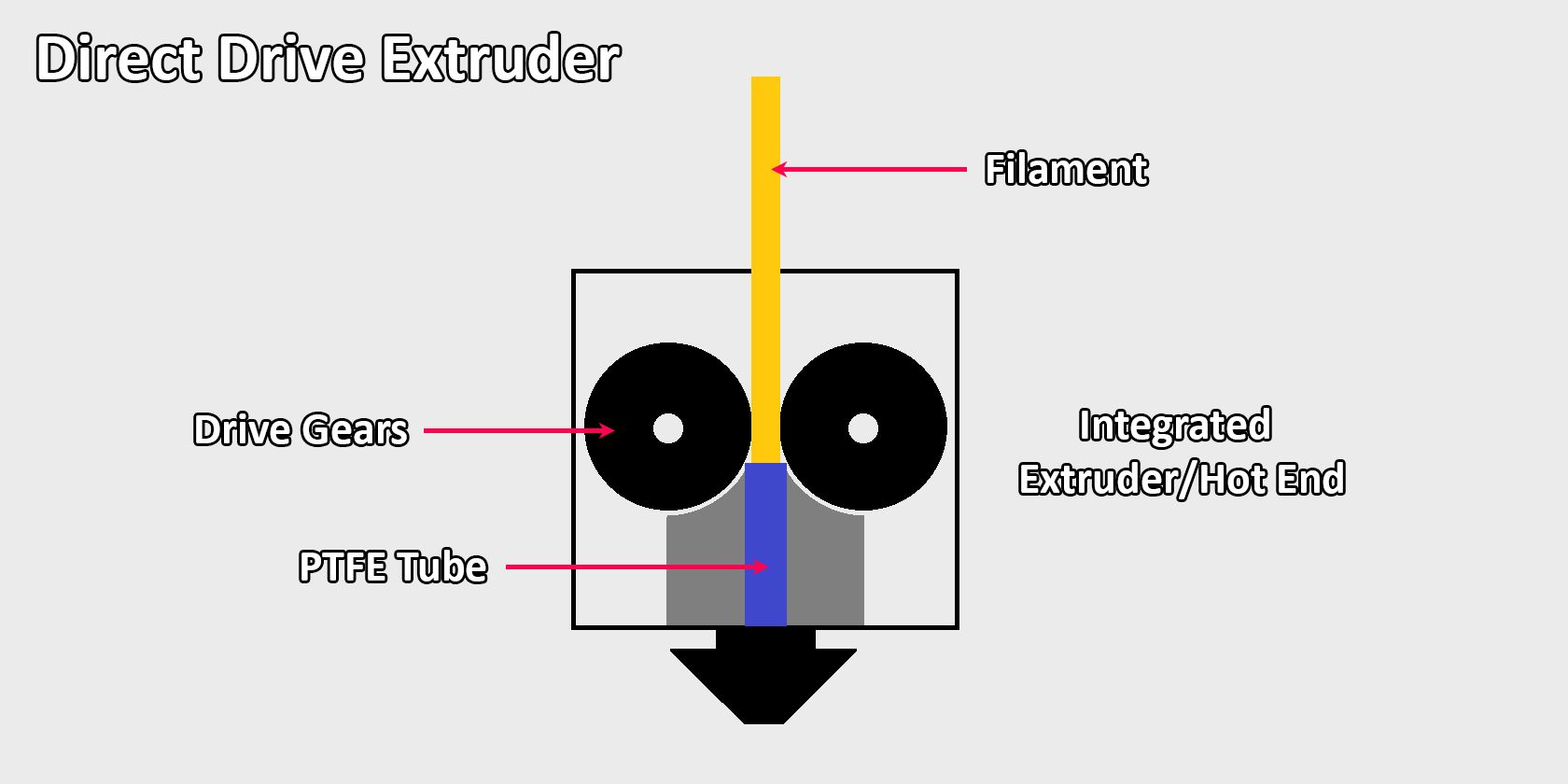

What Makes Direct Drive Extruders Higher?

This print head design combines the extruder and scorching finish meeting right into a single unit. The thought is to scale back the filament path by bringing the extruder as shut as doable to the nozzle. Doing so considerably shortens the size of filament that must be pushed down the PTFE tube. That additionally means a shorter part of the filament must push in opposition to the nozzle to generate extrusion strain.

A shorter part of filament is inherently stiffer and due to this fact much less prone to bunch up and clog on its approach to the nozzle. This enables direct drive extruders to print versatile filaments with ease, whereas additionally decreasing retraction distance settings for normal filaments. A shorter part of filament can be simpler to regulate with precision, which reduces stringing points evident in sophisticated 3D prints.

However Are They Actually Higher?

Direct drive extruders certainly make 3D printing with versatile filaments a breeze, however nearly everybody however complains of ugly Z-banding points after upgrading from Bowden to direct drive extruders. These gremlins manifest as ugly bands operating vertically throughout the print floor and are seen alongside the Z-axis of the 3D printer.

The severity of the banding can range from printer to printer, but it surely completely manifests in all direct drive extruders. I’ve personally used 5 totally different direct drive extruders, with every extruder exhibiting this difficulty to various levels.

And it isn’t simply me and some statistical outliers dealing with these points.

The Difficulty #602 Wasteland

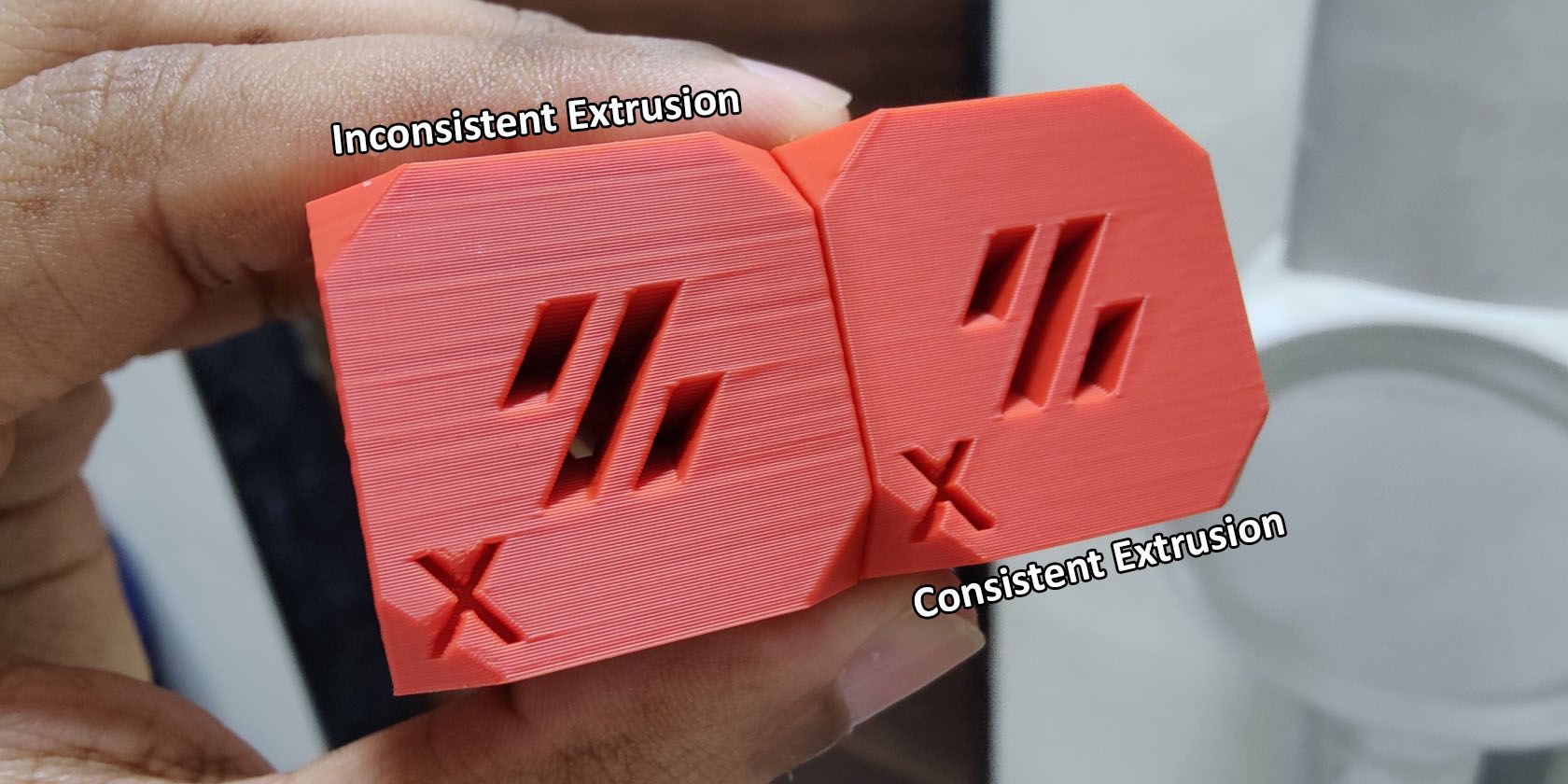

The house owners of Prusa direct drive printers had a collective meltdown after they realized that their costly machines couldn’t match the print high quality of the significantly cheaper Ender-3 printers. What began as a bug report citing inconsistent filament extrusion, ultimately spawned into the notorious Issue #602.

Josef Prusa, the proprietor and founding father of Prusa Analysis, responded by mobilizing his military of engineers to look into the matter, however the difficulty stays unsolved to today. There’s a whole Discord neighborhood, dubbed The 602 Wasteland, the place 3D printer lovers not solely lament and joke concerning the unsolved phenomenon in equal measure, however some even take a crack at fixing the difficulty.

Briefly, customers are to sure complain about this phenomenon as soon as 3D printers outfitted with a direct drive extruder attain a big sufficient put in consumer base. House owners of the wildly common Voron DIY 3D printers (see our Voron newbie’s information) know this phenomenon as Issue #6. You’ll find folks masking the tell-tale extrusion inconsistency by snapping pictures beneath favorable lighting situations, however the issue is squarely seen as soon as the 3D prints are shot beneath overhead lighting.

What Causes These Direct Drive Extrusion Points?

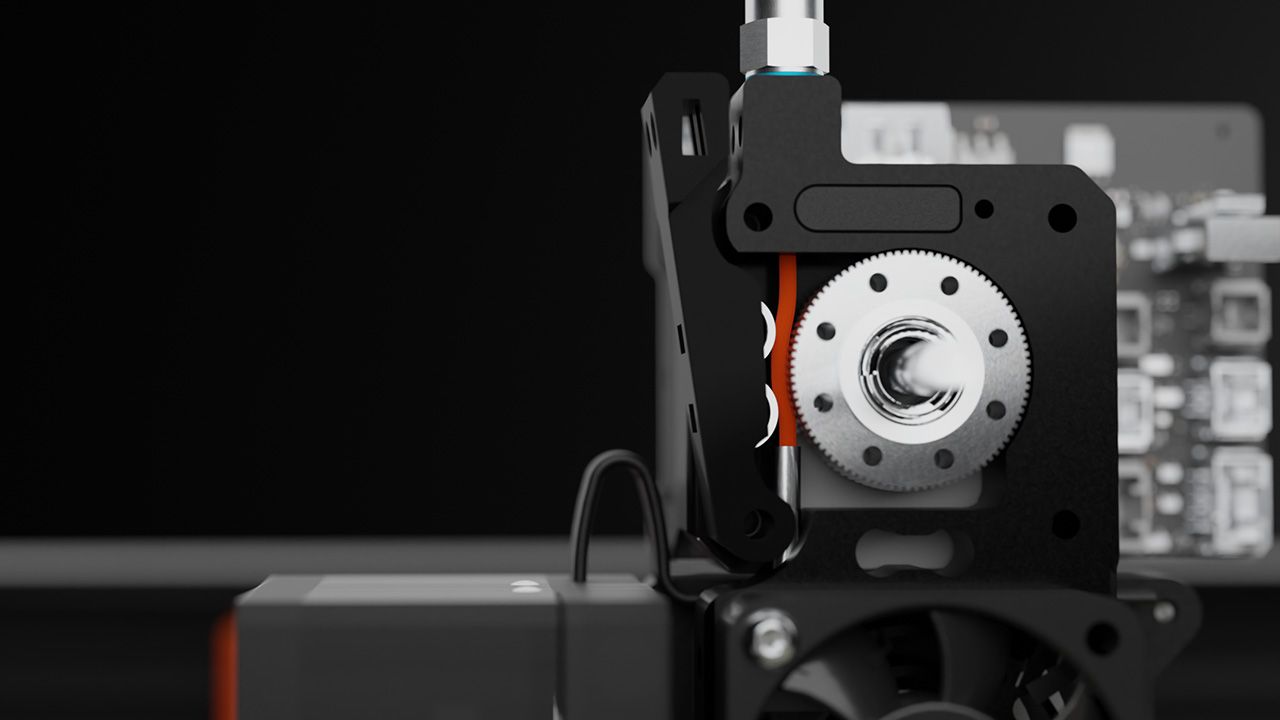

When you issue out improper meeting and tuning points, the main theories for the inconsistent extrusion related to direct drive extruders boil all the way down to the Bondtech’s “Twin Drive” extruder gears. These are the very same straight-cut pinion gears present in nearly each direct drive extruder utilized in common 3D printer designs from Prusa and Voron.

3D printing YouTubers Design Prototype Take a look at and MihaiDesigns have accomplished a terrific job of narrowing down the issue to Bondtech’s extruder gears, and the previous’s investigation is price trying out. Each YouTubers have urged utilizing helical or herringbone extruder gear design to eradicate the inconsistent extrusion difficulty.

As of this writing, neither Bondtech nor every other extruder maker has introduced an improved design to the market, but.

How Are Bowden Extruders Resistant to These Points?

Do you recall how we had dismissed Bowden extruders by illustrating how their filament feed design is tantamount to pushing a rope down a hose? Properly, having that diploma of slack, and the following delay in nozzle strain buildup, is ideal for ironing out extrusion inconsistencies arising out of poor direct drive extruder gear design.

The identical design shortcomings that stop Bowden extruders from having shorter retraction distances—and faster, extra responsive management over nozzle strain—additionally come in useful to forestall inconsistent extrusion artefacts from ever manifesting within the precise 3D printed objects.

Take a gander on the clear 3D print (and the dearth of Z-banding therein) obtained from my inventory Ender-3 printer outfitted with the Bowden extruder, in case you discover that tough to consider. I’ve used half a dozen totally different direct drive extruders since then, with out ever with the ability to obtain this stage of extrusion consistency.

Not surprisingly, some Voron 3D printer house owners nonetheless swear by and use Bowden extruders for this very motive. Nevertheless, doing so has just a few caveats.

Ought to You “Improve” to a Bowden Extruder?

You most actually shouldn’t in case you plan on printing versatile filaments, which completely want the shorter filament path of a direct drive extruder. Those that personal quick CoreXY printers are additionally higher off sticking with their direct drive extruders.

That is very true if they do not wish to sacrifice both pace or the superior strain advance function. It’s unattainable for Bowden extruders to drag off superior nozzle strain regulation at quick printing speeds. You completely want a direct drive extruder to print quick with strain advance enabled.

Extrusion inconsistency related to direct drive extruders isn’t the top of the world. Additive printing isn’t alleged to be aesthetically clear to start with, so minor Z-banding is appropriate.

Nevertheless, in case you are experiencing egregious extrusion inconsistencies, you’re higher off different possible causes corresponding to mattress warmth regulation, Z-axis binding, and filament movement fee.

Prusa XL’s Cycloidal Gear Extruder to the Rescue

Not everyone seems to be taking this drawback mendacity down. Prusa Analysis has made radical modifications to the brand new extruder design employed within the upcoming Prusa XL CoreXY printer, as mentioned intimately in our primer on the Prusa XL. Many consider that this design may remedy the Difficulty #602 that continues to plague current Prusa direct drive printers.

It’s a bit untimely to get our hopes up with the Prusa XL, but it surely positive beats persevering with to make use of the identical Bondtech direct drive extruder gears suspected to trigger the aforementioned extrusion points.

Direct Drive Extruder Points

As we’ve explored, whereas direct drive extruders do make 3D printing with versatile filaments far simpler, upgrading to 1 from a Bowden may end up in ugly Z-banding points.

I’ve personally made peace with the minor extrusion inconsistencies related to direct drive extruders with a view to reap the advantages of printing versatile filaments, lack of stringing, and with the ability to print actually quick. That’s a good cut price.

Learn Subsequent

About The Writer